Choisissez votre langue

Demander un devis

Durethan® Polyamide 6 & 66

- Accueil

- Produits du fournisseur

- Envalior

- Durethan® Polyamide 6 & 66

Versatility, Durability and Reliability

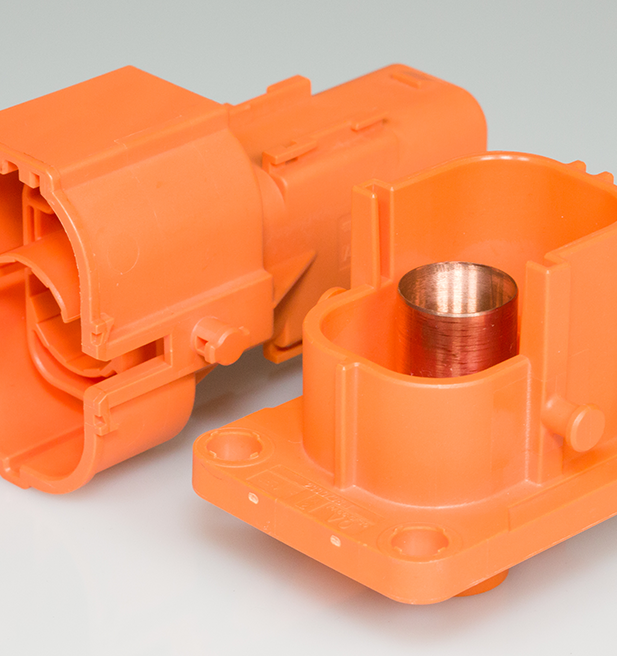

Durethan® is a high-performance engineering plastic produced by Envalior, a leading global specialty chemicals company. Durethan® encompasses a range of nylon materials, including Polyamide 6 (PA6) and Polyamide 66 (PA66), which are widely used in various industrial applications.

Durethan® Polyamide is chosen for its exceptional mechanical strength, heat resistance, and durability. It excels in applications where high-performance materials are needed, offering resistance to wear, chemicals, and moisture absorption. Its versatility, lightweight nature, and cost-effectiveness make it a popular choice in industries such as automotive, electrical, and industrial manufacturing, where it can withstand demanding conditions, maintain dimensional stability, and provide excellent design flexibility.

Due to its versatility and a wide range of advantageous properties, Durethan® Polyamide finds applications in numerous industries, including automotive, electrical and electronics, industrial machinery, consumer goods, and more. It's chosen for its ability to meet specific performance requirements while also being relatively easy to process and manufacture. Caractéristiques et propriétés de la gamme de produits :

Durethan® Polyamide is ideal for automotive applications due to its high mechanical strength, heat resistance, and low weight, which contribute to improved fuel efficiency and reduced emissions. Its durability and chemical resistance make it suitable for under-the-hood components, while its design flexibility allows for complex and lightweight structural parts. InElec® est habituellement utilisé dans les applications suivantes :

In construction and building applications, Durethan® Polyamide is utilized for components like window profiles, fasteners, and plumbing fixtures. Its resistance to moisture, chemicals, and temperature fluctuations ensures these components remain structurally sound and reliable over time, contributing to the overall safety and longevity of buildings and infrastructure. Applications courantes :

Durethan® Polyamide is employed in the manufacturing of various consumer goods, such as sports equipment, luggage, and appliances. Its lightweight yet durable properties make it a valuable choice for creating products that are both easy to handle and built to last, meeting the demands of consumers for high-quality and long-lasting items. Il est habituellement utilisé dans les applications suivantes :

In the electrical and electronics sector, Durethan® Polyamide serves as an excellent electrical insulator and offers superior dimensional stability. It helps ensure the safety and reliability of electrical components, such as connectors and housings, while its resistance to moisture and chemicals enhances long-term performance. Il est habituellement utilisé dans les applications suivantes :

Durethan® Polyamide's robustness, resistance to wear and abrasion, and ability to maintain dimensional stability under load make it a valuable choice in industrial machinery. It extends the lifespan of moving parts, reducing maintenance costs, and is favored for its adaptability to complex designs, enhancing overall machinery efficiency. Il est habituellement utilisé dans les applications suivantes :